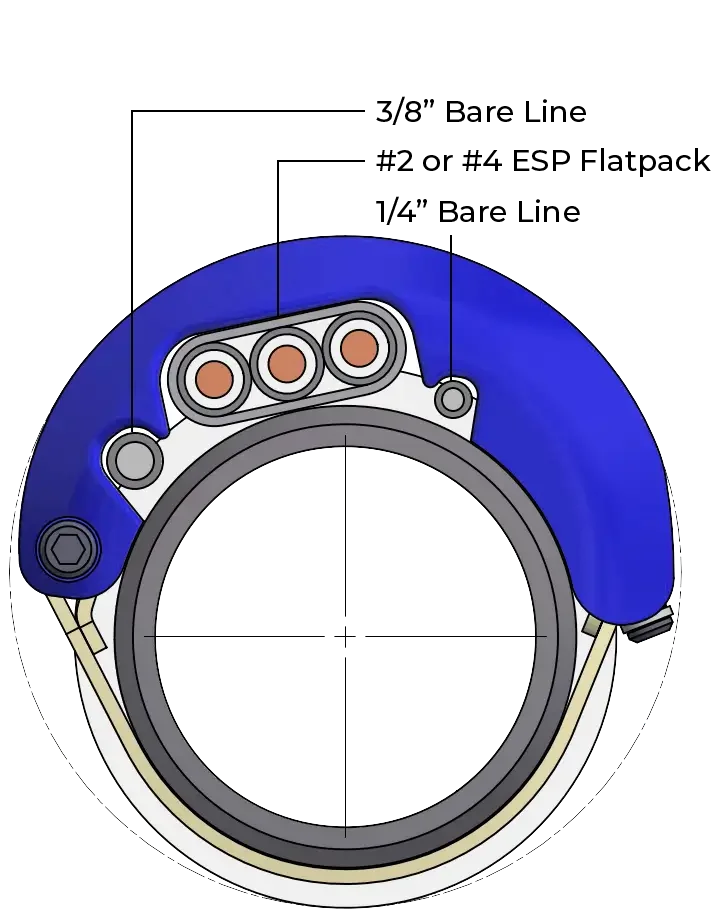

Cross Collar Clamp

Protecting your ESP investment. Engineered for the field.

Damaged ESP cables mean costly pulls, lost production, and unplanned downtime. Our Cross Collar Clamp is a premium slimline ESP cable protector built from cast low carbon steel and rolled steel straps, engineered in direct response to field failures our clients were experiencing. Fully NACE MR0175 compliant for sour service environments, the Cross Collar Clamp delivers a 40-ton load rating at 65% less weight than competitive products, with a universal slot design that accommodates both #2 and #4 ESP flatpacks in standard and tight hole applications.

-

Extends ESP cable life and reduces costly intervention with a purpose-built design that outperforms conventional clamps in the most demanding downhole conditions.

Universal slot design for #2 and #4 ESP flatpack and 1/4" and 3/8" bare control lines

Fully interlocking strap system - forces transfer to interlocking tab, not the bolt

Shouldered straps seat against tubing upset, preventing movement and promoting proper installation

Fully supported cable guard with 40-ton lateral load rating prevents cable crushing

Slim OD profile fits 5-1/2" 20# casing (4.653" drift)

Fully NACE MR0175 compliant - cast low carbon steel body and A193 B7M chromium-molybdenum alloy steel hardware

65% lighter than competitive products at 3.50 lbs

Anti-corrosive coated with fully captive hardware - no loose parts

Redressable - pulled, refurbished locally, and redeployed for better long-term value

Backed by 20+ years of industry design experience and 2M+ protectors downhole

-

PROBLEM:

Electric cables and control lines running on the outside of a tubing string are vulnerable during installation and throughout the life of the well. Any damage can create a short that shuts down an ESP or prevents chemical treatments from reaching the tubing string — resulting in lost production and costly intervention.

SOLUTION:

A PetroQuip Cross Collar Clamp is installed across every collar to secure ESP cables and control lines against the tubing string, preventing damage, entanglement, or slippage while maintaining the integrity of downhole operations. The fully interlocking strap design and shouldered straps eliminate the bolt shearing failures common in conventional clamps, while the fully supported cable guard protects lines from crushing under lateral load.

-

Tubing Size: 2-7/8"

Max Casing: 5-1/2" 20# — 4.653" drift

Clamp OD: 4.58"

OAL: 8.90"

Carrying Load: 250 lbs (100'+ of cable)

Axial Load Rating: 40 tons

Lateral Load Rating: 40 tons

Weight: 3.50 lbs

-

Combine the Cross Collar Clamp with PetroQuip's sand management solutions for comprehensive ESP protection.

SandMaze - ESP fallback prevention

SandStorm-E - ESP sand separation

Ready to protect your ESP investment?

Prevent cable failures and reduce costly interventions with proven ESP protection.

Operators around the world trust PetroQuip to deliver downhole equipment that performs in the most demanding environments. From standard ESP installations to complex applications, our engineering team can work with you to develop the solution for your specific well conditions, including custom configurations when standard products don't meet your requirements. Connect with our team to get started:

sales@petroquip.com | 936-931-0100 | Contact us | Follow us on LinkedIn