DOWNHOLE TECHNOLOGY EXPERTS

Global reach. Premium quality. Custom solutions.

Custom-engineered solutions designed to tackle operator challenges with unparalleled reliability and optimized well performance.

Services

Delivering high-quality, customized engineering and technical services to support your operations including torquing, testing, and threading capabilities.

Production

Production equipment that improves artificial lift system performance by reducing downtime, lowering operating costs, and extending the life of wells.

Completions

Completions solutions for onshore and offshore applications around the world. Custom-engineered for performance and reliability in any environment.

Renewables

Our proven expertise extends to alternative energy sectors with specialized equipment custom engineered for geothermal and carbon capture applications.

Trusted partners for major operators worldwide.

Our custom-engineered solutions tackle operator challenges with unparalleled reliability and optimized well performance.

We’ve delivered cutting-edge completion and production technologies to energy leaders across oil and gas, geothermal, and carbon capture sectors for 20+ years. From our Texas headquarters, we serve operators in 20+ countries with fast, customized solutions that extend equipment life and maximize production efficiency.

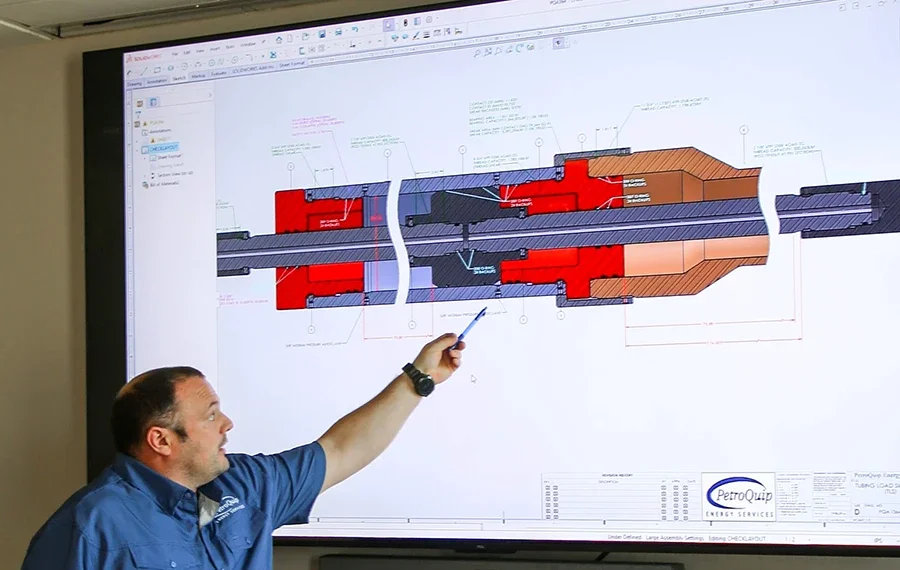

SINGLE-SOURCE PROVIDER

We eliminate the complexity of managing multiple vendors by providing design, engineering, threading, assembly, and testing support—all under one roof.

From initial concept through field deployment, we deliver fast timelines, quality control, and seamless execution for E&P and oilfield service companies worldwide.

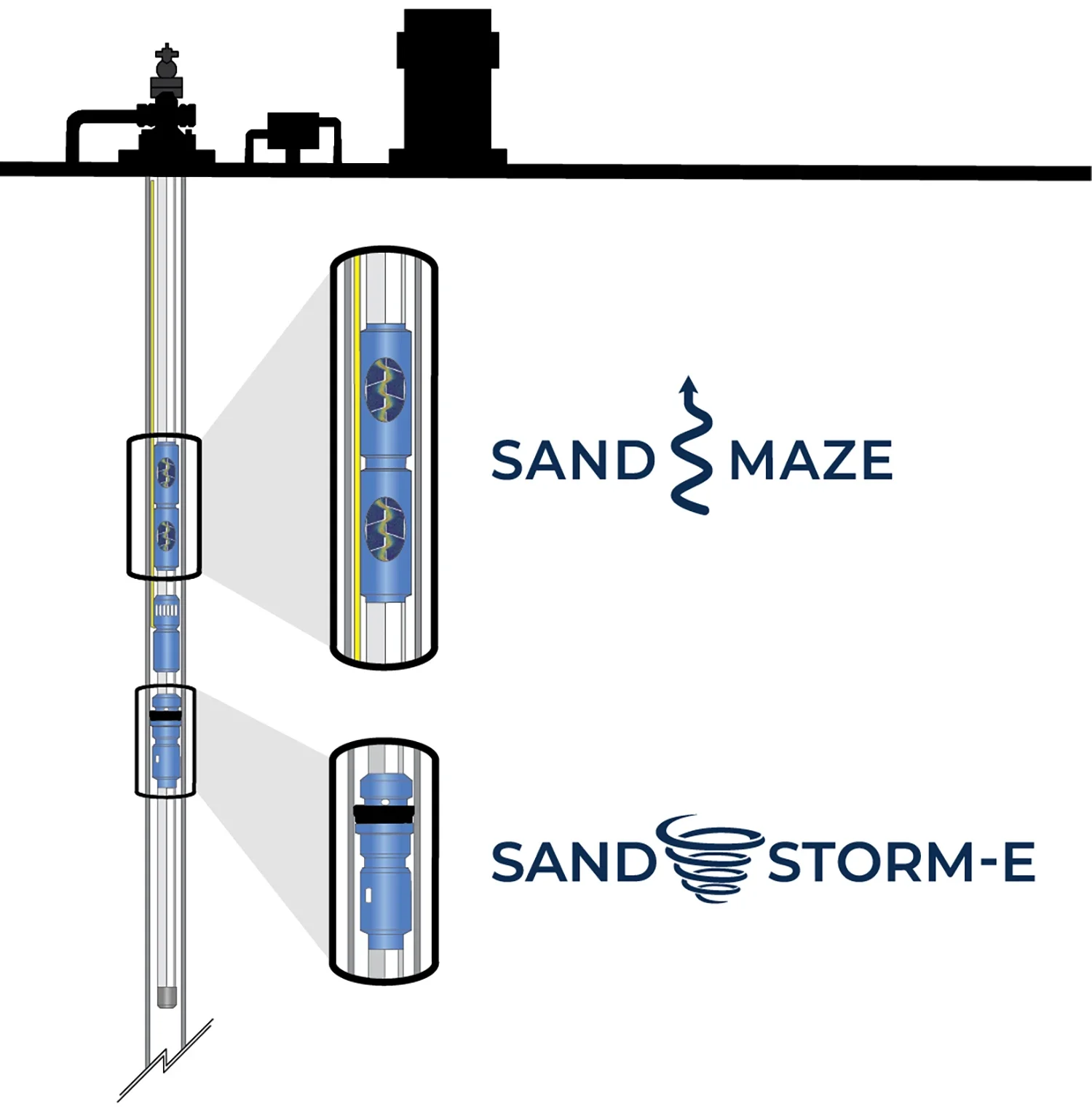

ESP Performance Solutions

Our integrated sand management solution combines SandMaze and SandStorm-E to provide comprehensive ESP protection. This dual-technology approach addresses both active production and shutdown periods, ensuring maximum equipment protection and operational efficiency throughout the lifecycle of the well.

Extend the life of your ESP

ESP Fallback Prevention

Captures sand during ESP shutdowns and self-cleans upon restart. Prevents sand settlement on pump stages while allowing injection treatments through bi-directional flow.

ESP Sand Separation

Separates sand from fluid before it reaches ESPs with minimal pressure drop. Fin-free vortex design ensures extended tool life and handles all ESP flow rates with one tool size.

VIDEO: Watch our animation to see how SandMaze and SandStorm-E work together to extend the life of ESPs.

Your well's profitability depends on equipment that works. Every time.

Operators worldwide trust our production solutions to prevent the sand damage and equipment failures that cost thousands per day in lost production. From the harshest offshore environments to the most demanding unconventional wells, our equipment performs when everything's on the line.

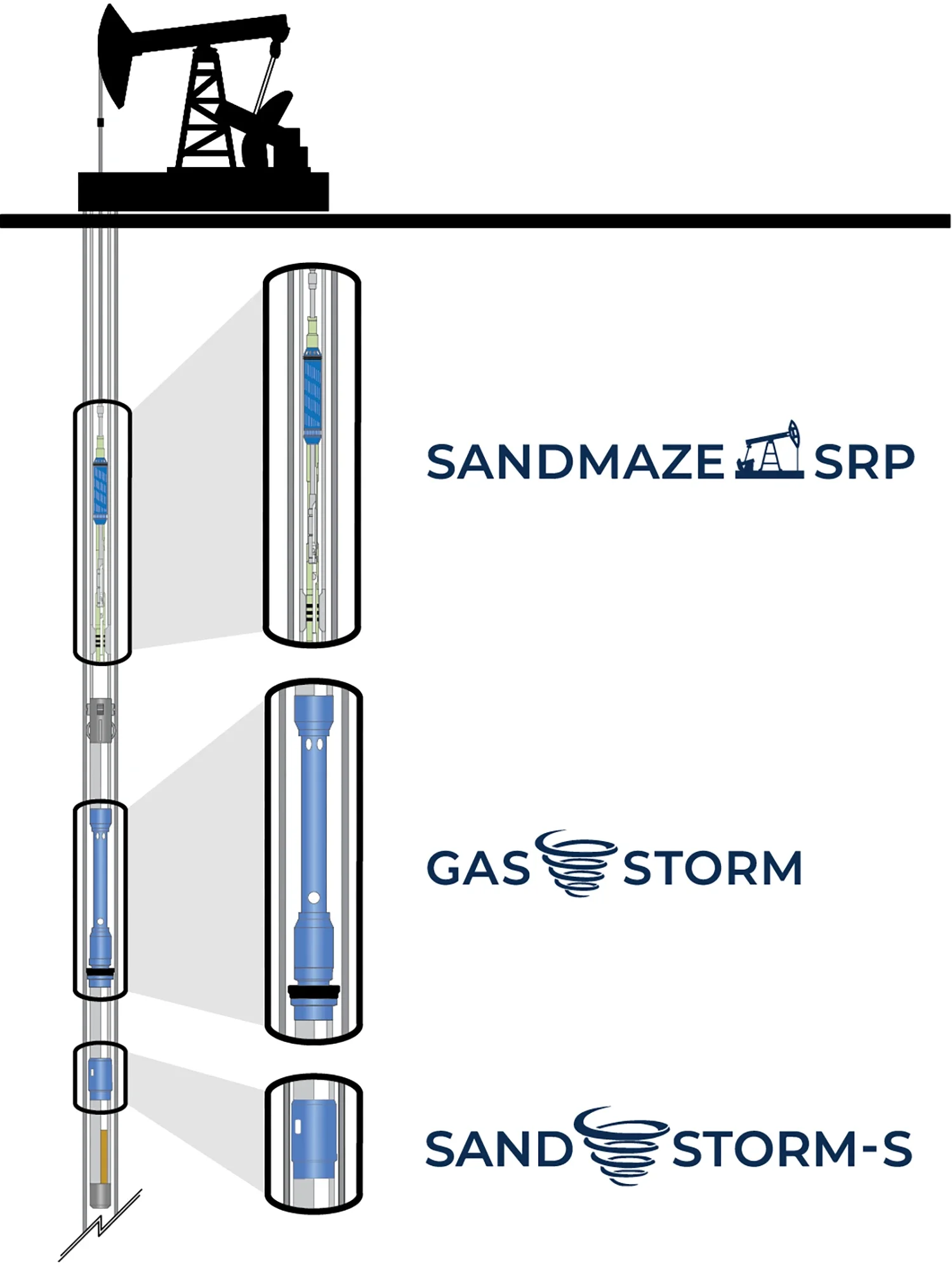

SRP Protection Solutions

Our advanced sucker rod pump protection solution combines SandMaze SRP, GasStorm, and SandStorm-S to maximize SRP performance and equipment life by addressing the primary causes of SRP failures (sand fallback, gas interference, and sand damage) with purpose-built tools designed specifically for SRP applications.

Protect your SRP

SRP Fallback Protection

Prevents sand fallback in SRPs with an innovative self-cleaning design that auto-activates during pump restart. It integrates seamlessly with existing configurations in only 48" OAL.

SRP Gas Separation

Compact gas separation for SRPs with no moving parts for maximum reliability and efficiency. Utilizes large annular area for superior separation efficiency in less than 6' OAL.

SRP Sand Separation

Removes sand before reaching SRPs with over 90% efficiency at 50-800 bbl/day flow rates. Purpose-built geometry optimized specifically for lower SRP flow conditions.

VIDEO: Watch our animation to see how SandMaze SRP, SandStorm-S, and GasStorm work together to protect SRPs.

Completions solutions for onshore and offshore applications worldwide with tools engineered for performance and reliability in any environment.

From conventional vertical wells to the world’s most challenging horizontal wells, our completion technologies deliver consistent performance across diverse operating conditions. We offer a range of mechanical and hydraulic sliding sleeves, completion accessories for control line management and tubing movement, and specialized tubular accessories that simplify installation while maintaining system integrity.

Extend the life of your well →

Made in Texas

PetroQuip tools are designed, engineered, and manufactured in Texas and Louisiana by our experienced engineers who understand oilfield challenges. Our customers rely on that Texas craftsmanship for fast, dependable lead times, consistent quality, and equipment that performs downhole when everything's on the line.

Solutions for renewables engineered for extreme environments with temperatures up to 450°F and pressures reaching 7,500 psi.

Our Utah FORGE award-winning technology has been field-proven in 450°F environments. When traditional geothermal systems struggle with high-temperature reservoir contact, our proprietary multi-stage approach delivers consistent performance and reliability.

Explore solutions for renewables →

The PetroQuip Foundation

Giving back to the communities where we live and work.

For every SandMaze, SandMaze SRP, SandStorm-E, SandStorm-S, and GasStorm tool sold each year, we contribute a portion of those proceeds to The PetroQuip Foundation. At the end of each fiscal, our customers get to direct these funds to their chosen 501(c) charity creating positive impact in communities where we work and operate together.