Capture fallback and extend the life of your ESP.

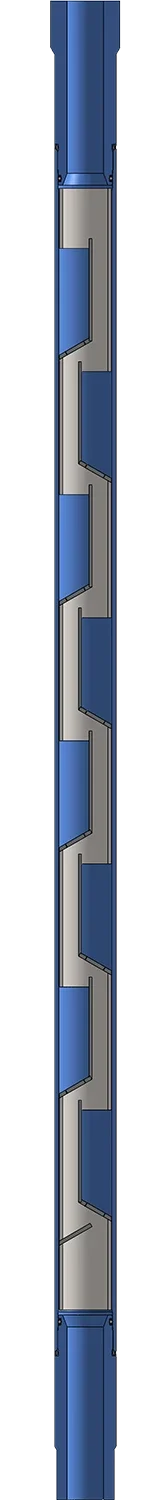

SandMaze

Capture fallback and extend the life of your ESP.

PetroQuip's SandMaze keeps sand out of your ESP by capturing sand, proppant, and debris fallback during production shutdowns. The proprietary flow path design directs particles into holding chambers when the ESP is offline, preventing sand from settling on or in the pump's stages. Once flow is re-established, SandMaze's self-cleaning feature allows captured sand to re-enter the production stream without aggressive jetting. Designed for ESP wells with frequent sand-related failures.

-

Extends ESP life by preventing hard pump starts caused by sand settling on pump stages

Captures sand and proppant fallback in holding chambers when ESP is offline

Self-cleaning feature safely reintroduces captured sand into production flow on restart - no aggressive jetting required

Bi-directional flow allows for injection treatments

No communication to the annulus

Minimizes erosion to the outer body of the tool

Over 400 units installed globally across the Bakken, Permian Basin, and international markets

Combine with SandStorm-E for comprehensive ESP protection during production and shutdowns

A portion of proceeds from every unit sold goes to The PetroQuip Foundation.

-

PROBLEM:

When an ESP shuts down, sand settles on top of or gets lodged inside the pump's stages. Upon restart, this creates "hard start" scenarios that overstress the motor, accelerate pump wear, and cause premature failures.

SOLUTION:

PetroQuip's SandMaze captures sand, proppant and debris fallback during production shutdown, preventing permanent damage and significantly increasing ESP run time in unconventional applications.

The proprietary flow path design captures sand in specialized holding chambers when the ESP is offline. Once flow resumes, the self-cleaning feature (based on proven gravel pack screen technology) allows captured sand to safely re-enter the production stream. Unlike competitive tools, no aggressive jetting is required, which significantly reduces the risk of cutting through the outer chamber.

-

SandStorm-E - Separates sand before it reaches the ESP

VIDEO: SandMaze + SandStorm E

Watch the animation below to see how SandMaze and SandStorm-E work together to prevent fallback and extend the life of ESPs:

VIDEO: SandMaze in Action

Watch our timelapse video below to see how the SandMaze capture and clean-out process works:

How it works:

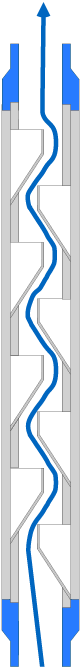

SandMaze operates through four distinct phases that provide continuous ESP protection throughout the production cycle.

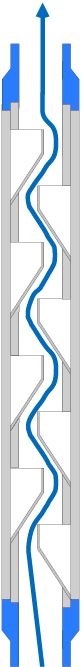

Production Mode:

Normal fluid flow through the tool during ESP operation

Sand particles flow through without restriction

STAGE 1

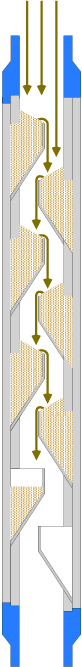

ESP Off / Sand Captured

When ESP shuts down, sand settles into holding chambers

Prevents sand accumulation on pump stages

STAGE 2

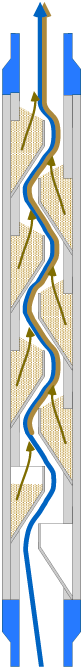

ESP Restart / Sand Flushing

Self-cleaning feature activates when production resumes

Captured sand safely re-enters production stream

STAGE 3

Back to Clean

Tool returns to normal production mode

No aggressive jetting required

STAGE 4

Stop sand-related ESP failures.

Protect your ESP investment with proven fallback prevention technology. Our engineering team will work with you to design a comprehensive sand management solution for your operations.

Email: sales@petroquip.com

Phone: 936-931-0100