Extend ESP life with over 90% efficiency.

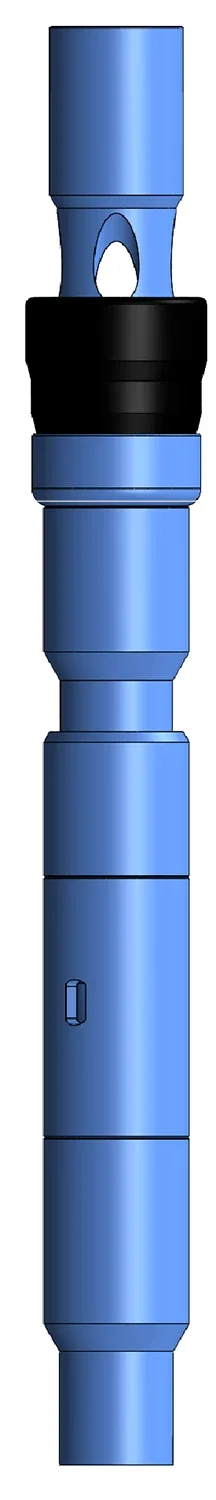

SandStorm-E

Extend ESP life with over 90% efficiency.

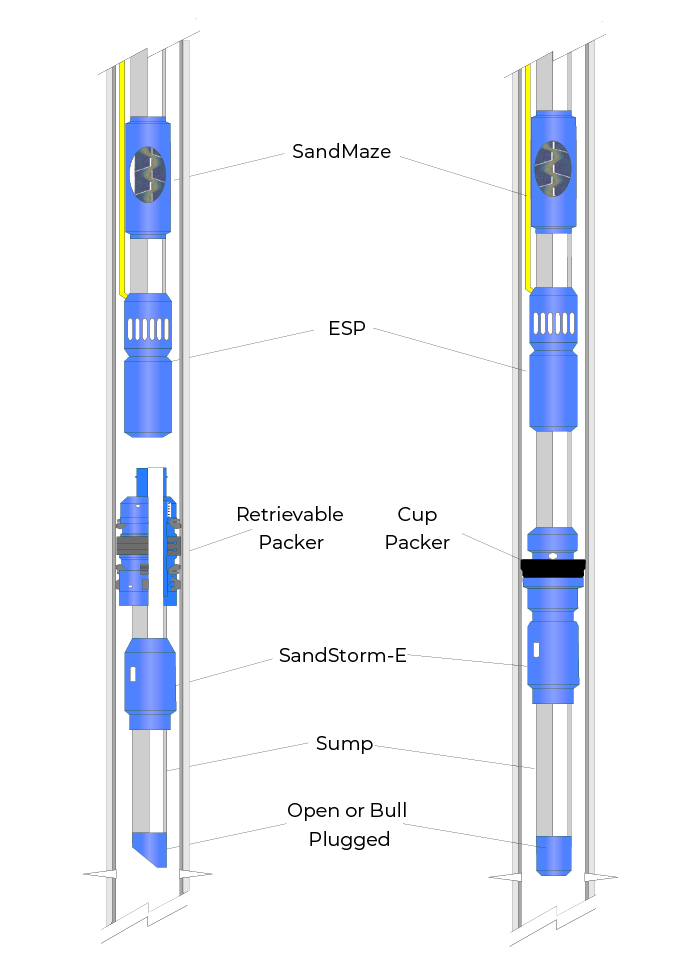

PetroQuip's SandStorm-E separates sand and other solids from produced fluid before they reach your ESP. The vortex created inside the tool pushes debris down into a sump or tail pipe below and allows clean fluid to reach the pump. Its fin-free design ensures extended tool life. Designed for ESP wells with frequent sand-related failures.

-

Extends ESP life by separating sand and solids from produced fluid before they reach the pump

One size accommodates all ESP flow rates

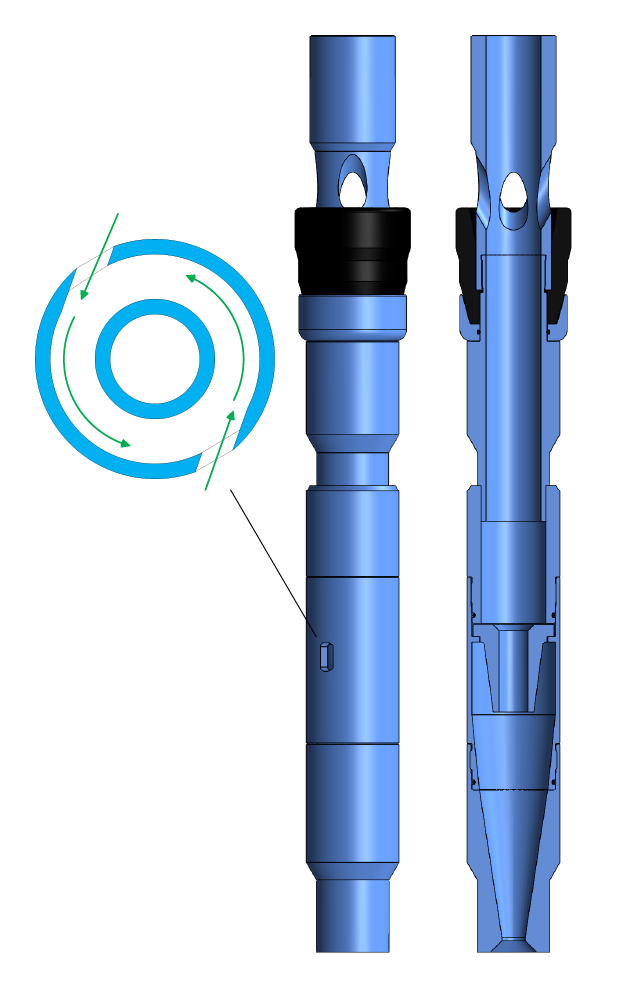

Fin-free vortex design eliminates internal erosion for longer tool life

Internal components hardened with Tungsten Carbide to reduce wear

Minimal pressure drop maintains production efficiency

Flexible installation - integral cup packer or retrievable packer options

Multiple tubing / casing compatibility by changing packer cups

Combine with SandMaze for comprehensive ESP protection during production and shutdowns

A portion of proceeds from every unit sold goes to The PetroQuip Foundation.

-

PROBLEM - Sand and solids in produced fluid cause abrasive wear on ESP stages, leading to reduced efficiency, premature equipment failure, and costly workovers.

SOLUTION - PetroQuip's SandStorm-E separates sand and other solids from produced fluid before they reach your ESP, protecting equipment and extending operational life.

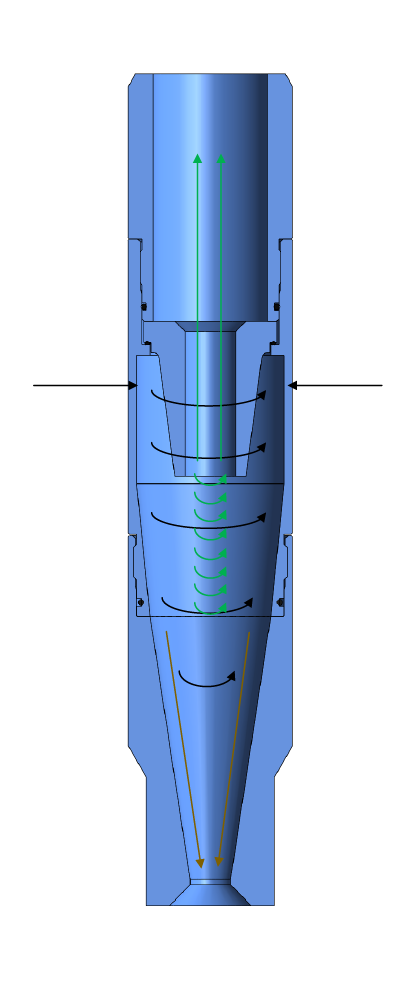

Fluid enters through ports tangentially, creating a powerful vortex that initiates separation. Heavier sand particles are pushed outward to the tool's inner diameter while lighter produced fluids move to the center. Two separate cyclones form: the outer cyclone pushes debris down into the sump below, while the inner cyclone flows upward to the ESP.

-

SandStorm-E with Cup Packer

VIDEO: Watch our animation to see how SandMaze and SandStorm-E work together to extend the life of ESPs.

How it works:

Flow enters through a port tangentially here. The way the flow enters creates the vortex that starts the separation of the heavy solids from the fluid.

As the flow enters the ports and starts to spin (black is both sand and produced fluids), the heavier sand particles are pushed to the ID of the SandStorm-E, and the lighter (green) produced fluids are pushed to the center of the SandStorm-E. There becomes two separate cyclones of lighter and heavier fluids and particles spinning. The heavier (brown outer cyclone) is pushed down the cone into the sump below. The lighter (green inner cyclone) is sucked up the hole by the ESP above.

Run Separately with a Retrievable Packer

Run with ESP and Cup Packer

Extend ESP life. Reduce costly workovers.

Contact our team today to discuss how SandStorm-E can protect your equipment and reduce costly workovers. Our team will help you determine the right configuration for your specific well conditions.

Email: sales@petroquip.com

Phone: 936-931-0100