Keeps fallback out and SRPs running.

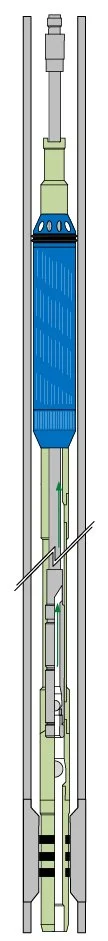

SandMaze SRP

Keeps fallback out and SRPs running.

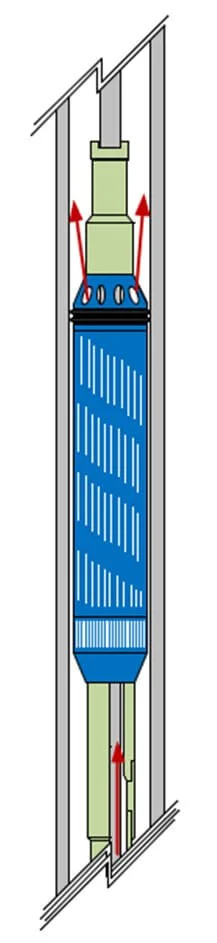

PetroQuip’s SandMaze SRP prevents sand and debris from falling back into the barrel of a SRP. Sand can damage the barrel and plunger, reducing pump efficiency and leading to pump failure. The SandMaze SRP uses a proprietary check valve system that stops sand from re-entering the barrel and plunger while allowing fluid to pass. It captures sand and debris when the pump is off and flushes them out when the pump is restarted. Designed for SRP wells experiencing frequent sand-related pump failures.

-

Keeps fallback debris out of plunger and barrel, extending SRP run life

Self-cleaning design captures debris when pump is off, flushes on restart

Reduces costs by minimizing pump replacements and workovers

Multi-well field trials saved one customer an estimated 3 workovers per well in 6 months

Designed as integral part of SRP (runs and pulls with the pump)

Minimal addition to SRP overall length (48" OAL)

Available in 2-3/8" & 3-1/2" tubing sizes

Rated to 350°F

A portion of proceeds from every unit sold goes to The PetroQuip Foundation.

-

PROBLEM:

When an SRP shuts down, sand and debris fall back into the barrel, damaging the plunger and barrel. This reduces pump efficiency and leads to premature pump failure, costing operators thousands in replacements and lost production.

SOLUTION:

PetroQuip’s SandMaze SRP uses a proprietary check valve system that prevents sand from re-entering the barrel and plunger while allowing fluid to pass.

During normal operation, fluids and sand are pumped straight through the filter. When the pump shuts off, sand falls back but is prevented from entering the barrel by the check valve system. The sand is captured in the filter chambers. When the pump restarts, flow through and around the filter cleans out captured sand, allowing it to re-enter production. The tool returns to normal operation with the filter clean.

-

SandStorm-S - Sand separation for SRP applications

GasStorm - Gas separation for SRPs

VIDEO: Watch our animation to see how SandMaze SRP, SandStorm-S, and GasStorm work together to protect SRPs.

How it works:

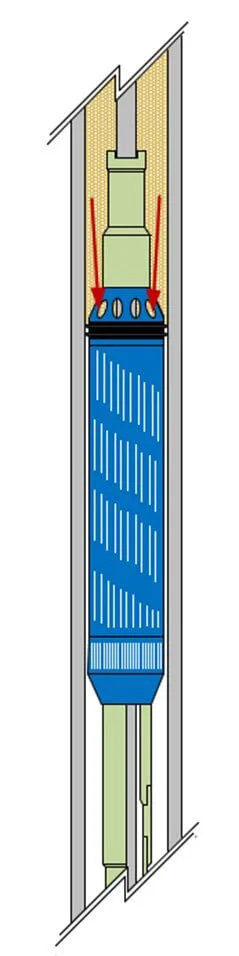

Fall Back

The pump is off and sand falls back into the filter

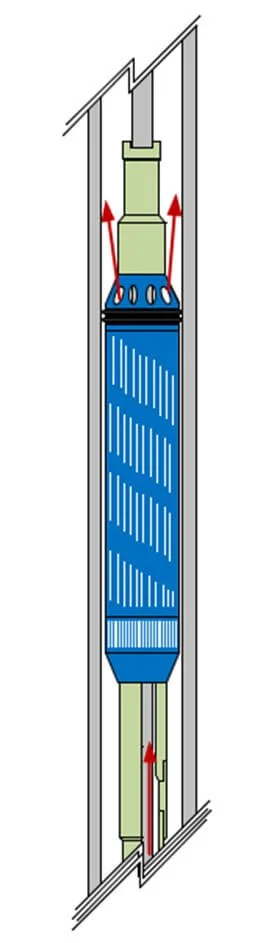

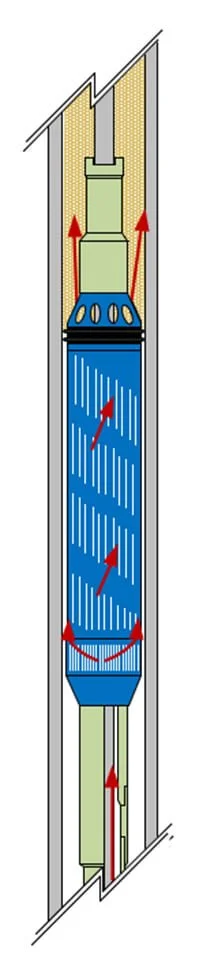

Normal Operation

Fluids and sand are pumped straight through the filter

Clean Out

Pump is back on, and the filter is cleaned by flow through and around the filter

Normal Operation

Fluids and sand are pumped straight through the filter

Ready to optimize your operations?

Our proven SRP fallback prevention technology is delivering real cost savings for operators. Contact us today to discuss how SandMaze SRP can benefit your operations.

Email: sales@petroquip.com

Phone: 936-931-0100